The GMP SPA was founded in 1972 but is part of a group of companies which has been active in the stone industry for over 100 years.

In the last century the activity was limited to the extraction of white Carrara marble, then the production of slabs of other Apuan marbles started.

After 1950 the production and processing of some classic colored marbles began and finally after 1960 the plant in Dogana di Ortonovo was built where the production and distribution of both Italian and foreign granites began.

Currently, the company has also offices and depots throughout Italy and subsidiaries in the United States.

The concessions of GMP, the Fantiscritti and the Caldia® quarries ,situated in the most important marble basin of the world are where the precious Bianco Carrara, Bianco Venato, Bardiglio Nuvolato, Calacatta Caldia®, Statuario Caldia® are extracted.

The GMP also extracts, buys and works granite and marble from all over the world ensuring, through exclusive contracts with producers the availability of a wide range of high quality products at competitive prices.

The GMP production is split between blocks, slabs and cut-to-size both for internal and external use.

In the last century the activity was limited to the extraction of white Carrara marble, then the production of slabs of other Apuan marbles started.

After 1950 the production and processing of some classic colored marbles began and finally after 1960 the plant in Dogana di Ortonovo was built where the production and distribution of both Italian and foreign granites began.

Currently, the company has also offices and depots throughout Italy and subsidiaries in the United States.

The concessions of GMP, the Fantiscritti and the Caldia® quarries ,situated in the most important marble basin of the world are where the precious Bianco Carrara, Bianco Venato, Bardiglio Nuvolato, Calacatta Caldia®, Statuario Caldia® are extracted.

The GMP also extracts, buys and works granite and marble from all over the world ensuring, through exclusive contracts with producers the availability of a wide range of high quality products at competitive prices.

The GMP production is split between blocks, slabs and cut-to-size both for internal and external use.

Thanks to the wide selection of products and large stocks of material in its depots GMP is able to satisfy all customers’ demands in terms of quality and quantity.

A young and dynamic sales network projects the GMP in a worldwide market.

A young and dynamic sales network projects the GMP in a worldwide market.

The main target markets are:

- Italy: the main factory and the five branches assure us a widespread coverage of the country.

- USA

- Europe

- Africa

- Middle east

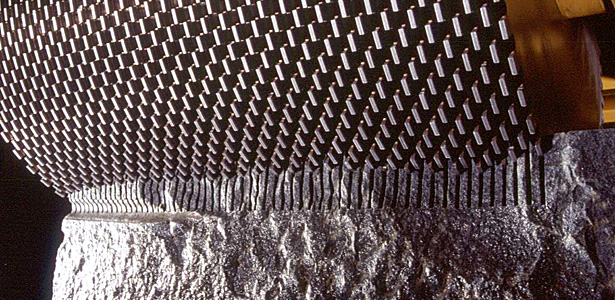

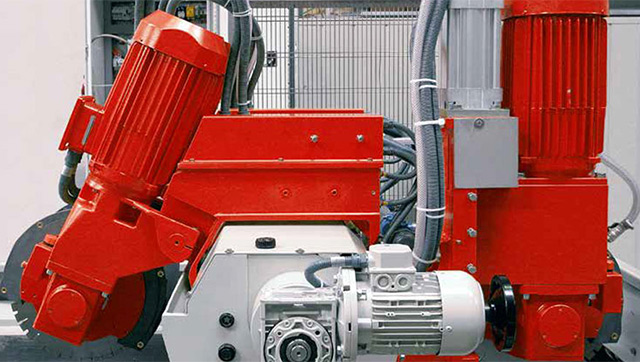

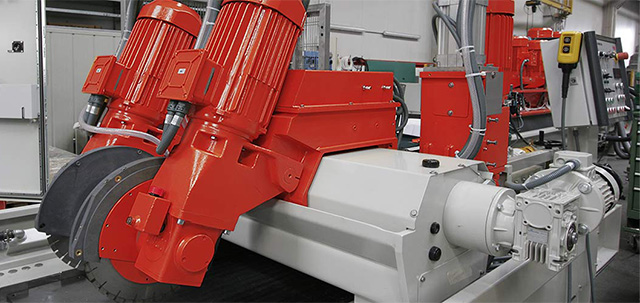

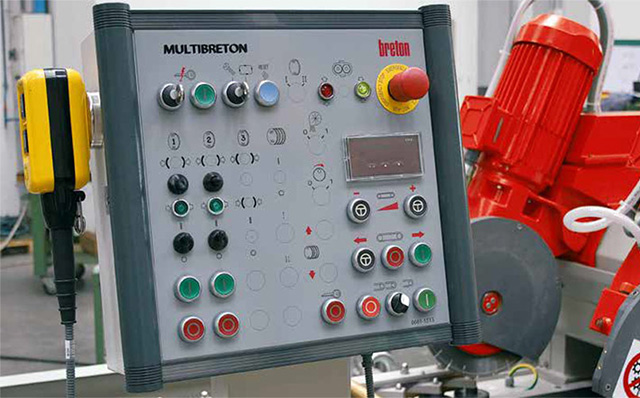

SIAC was looking for a slab polishing line that could meet its expectations in terms of production efficiency and improvement of quality standards, and found the best solution in Breton’s “Luxmaster KFT 5000”.

“Our Breton plant consists of: a loading slab Jot, a Luxmaster KFT 5000 polishing machine with 18 spindles, an automatic waxing machine, an automatic applicator of the protective polyethylene sheet and an unloading slab jot.

The use of a such machinery was immediately clear and intuitive. We have seen improvements in terms of quality and quantity and an increase in production.”

A satisfaction for SIAC that can also be measured by the post-sales service guaranteed by Breton.

“During the first months of regular production, several times we had to rely on Breton assistance several times to solve some hitches while testing. Online assistance personnel, like technicians/installers, have shown themselves to be punctual, professional and determined to solve our problems in every situation”.

In fact, Breton guarantees a hotline service that is active 24 hours a day, thanks to the company sites in the United States, China, India, Australia and Brazil: a telephone service provided by highly specialized technicians, who are also able to carry out technical work directly on the machine installed at the customer plant, without the need for the operator’s presence.

For more information and prices, on the Luxmaster KFT 5000, contact mail@breton.it.

In fact, Breton guarantees a hotline service that is active 24 hours a day, thanks to the company sites in the United States, China, India, Australia and Brazil: a telephone service provided by highly specialized technicians, who are also able to carry out technical work directly on the machine installed at the customer plant, without the need for the operator’s presence.

For more information and prices, on the Luxmaster KFT 5000, contact mail@breton.it.

We’ll get back to you promptly.

Thank you for the attention and best regards.

Bye-bye

Sergio Prior