Good morning,

I wish to inform you that, besides a polishing line for granite slabs “Levibreton KG 4000 PLUS”, we installed the first Breton resin-treating line using microwaves at CERESER MARMI, a company that has been working marble and granite for quite a while.

ADVANTAGES OF THE LINE

.

- IMPROVED RESTORATION OF THE SLAB, ensuring excellent results.

.

- POLISHING IS ENHANCED: resin betters polishing.

.

- REDUCTION OF WAIT TIMES: products are available for immediate delivery.

A loader with vacuum cups lifts the material from the A-frame supporting the “humid slabs” (installed on a rotating platform).

The work cycle of this automatic loader makes it possible to process slabs arranged in the "diamond-match" pattern as well.

The work cycle of this automatic loader makes it possible to process slabs arranged in the "diamond-match" pattern as well.

After being rotated 90°, the slab is conveyed to a station which is used as a bypass unit, meaning that catalyzed slabs can be unloaded and humid slabs (in transit to the conveyor) can be loaded at the same time.

Once the time required for drying is over, both the platform and the slab are removed and placed on the conveyor that transfers them to the resin-treating station. If slabs are to be reinforced, the operator applies automatically a fibreglass net on the material surface using the suitable device.

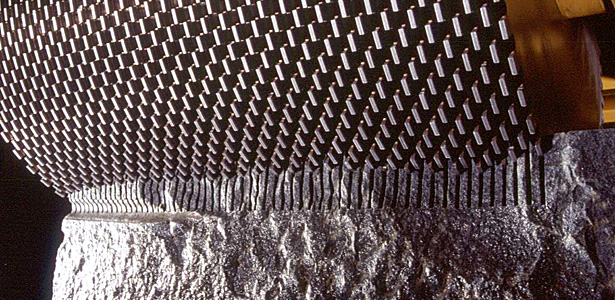

The application of the specific resin for microwaves on the slabs, either to beautify them or to glue the net, is executed automatically under the spray-gun of the resin-treating unit.

Slabs pass through the catalysis kiln one by one, according to the cycle time of the line.

MICROWAVE OVEN TECHNICAL DATA SHEET

- oven type: microwaves and hot air

- total power: 250 kW

- microwave unit: 9+9 magnetrons (microwave generators)

- air unit: 8 fans for magnetron cooling

- air recirculation unit: 4 fans for air recirculation + 1 fan for steam extraction

- dimensions: 9.74 x 3.16 (h) x 2.15 m

- surface: 30 sq.m

- cycle time: 4 min./slab

- production rate: 15 slabs/hour

- shielding: microwave-specific shielding

- insulation: 50 mm rockwool panels

After a possible manual retouching with resin, the unit transfers the supporting platforms to the lower conveyors.

The platforms with the resin-treated slabs are then conveyed to the cooling area of the catalysis station.

After a few minutes, cooled slabs are unloaded and conveyed to the bypass station where they are lifted so that the humid slabs can pass below.

The finished slabs are rotated 90° so that the automatic offloader can lift and unload them on the A-frame supporting the “resin-treated slabs” (installed on a rotating platform).

The finished slabs are rotated 90° so that the automatic offloader can lift and unload them on the A-frame supporting the “resin-treated slabs” (installed on a rotating platform). Well, that’s all for today.

Well, that’s all for today.

I hope the resin-treating process of this Breton line is clear enough.

By-By

Sergio Prior